COPPER MONOLITHIC BULLETS

Copper monolithic bullets are soon going to replace copper plating lead bullets. Many manufacturers decided to produce them not only moved by an ecological need, but also by a performance one. But just like every factory is different from the other ones, every bullet is unique. Results are directly proportional to innovation and motivation.

Today, Hasler is leader in the research of precision shooting. Our team of experts, lead by award-winning Giuseppe De Pasquale, has developed a superior–quality monolithic copper bullet with high attention to details. This is the best monolithic bullet you’ll find.

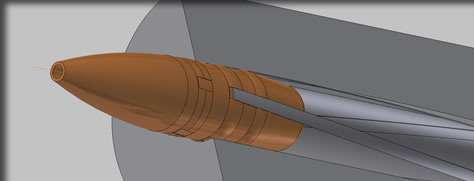

WHY CHOSE THE UNDERCALIBRE BULLET HASLER ?

Thanks to their O-ring structure, Hasler monolithic bullets have a diameter slightly inferior to the caliber needed by the barrel. The rings on the structure touch the grooves on the barrel, while the rest of the bullet doesn’t.

So, while traditional bullets are in contact with the whole surface of the bore, thus producing a lot of friction, heat and counter-pressure, Hasler bullets guarantee a reduced friction and therefore higher speed.

You can choose to use slightly faster burning powders so as to have better results and keep your barrels from excessive traumas. And don’t forget that thanks to this improvement the shooter will be definitely less stressed.

Using these bullets, shots will be very fast without exceeding the pressure limits for each caliber.

THE HIGH QUALITY COPPER MAKES THE DIFFERENCE

The high-quality copper alloy used to make Hasler bullets offers homogeneity and ductility, hence making the difference both when shooting and on impact.

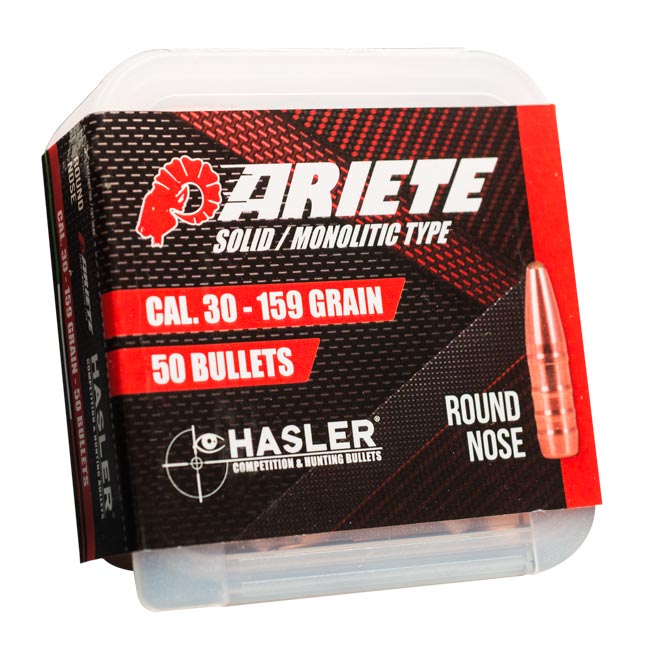

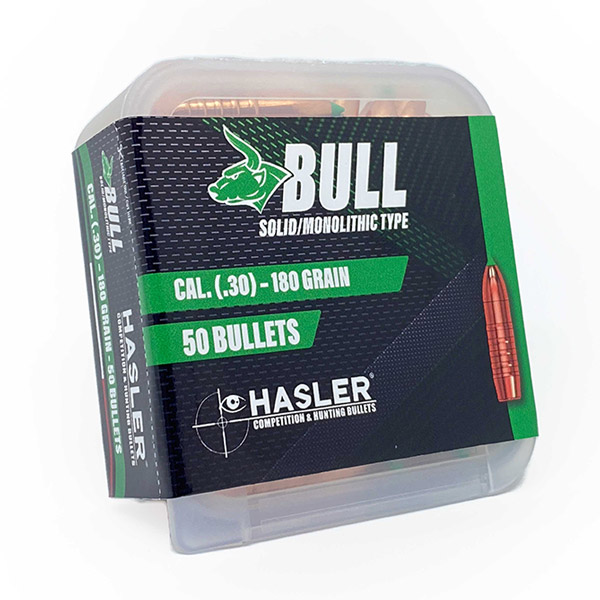

FIVE LINES OF PRODUCTS

Hasler products aim at being the most innovative in the field of monolithic copper ogives. They offer qualitative excellence in all three ballistic fields.

Hasler bullets are under-caliber ogives with circular and semi-circular o-rings, like high-caliber cannons. They offer ground advantages for precision lovers:

- low friction coefficient between bullet and barrel as the contact surface between lands and grooves is less extended than the one in a conventional bullet.

- High ballistic coefficient which together with the low friction gives high speed and so fast shots even using short barrels.

- Considerable reduction in the barrel wear due to minor contact surface and easier bullet flow.

- Top quality materials and a design studied to obtain maximum performance and precision, both in sport and hunting (where Hasler offers an excellent terminal effect).

- Standard weight deviation is inferior to one-tenth of a grain and dimension deviation is inferior to +-3 micron per lot.

Hasler ogive has always given the best results with every caliber and barrel tested, with the only exception of polygonal rifling barrels for which we discourage the use of our ogives.